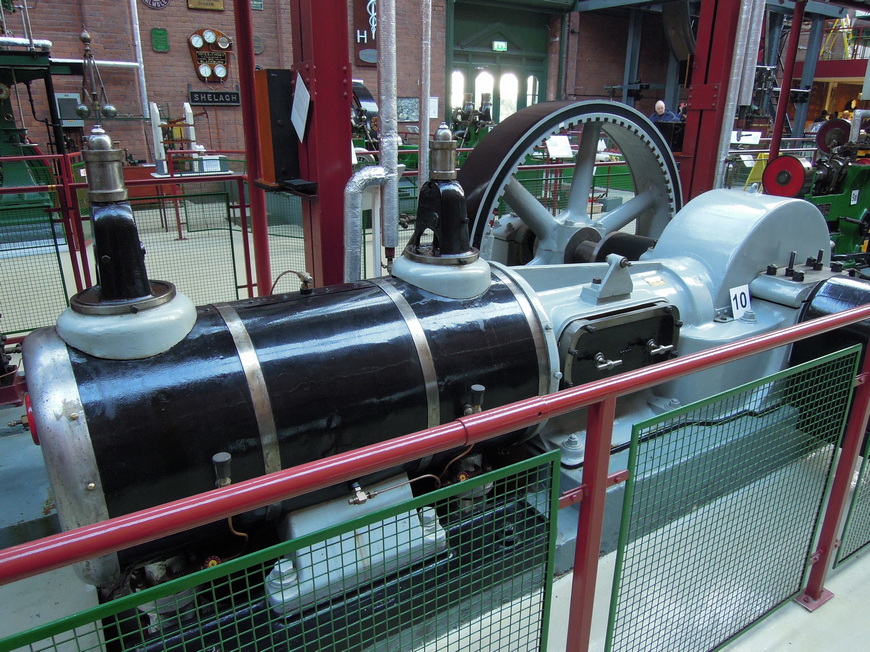

Horizontal Uniflow Single Cylinder

The uniflow engine was perhaps the final development of the reciprocating steam engine and enabled it to reach higher levels of operating efficiency than had previously been achieved. In a conventional engine, the admission of hot steam from the boiler followed by exhausting to the (colder) condenser at the same end of the cylinder on every stroke results in condensation and wasted energy as the cylinder is repeatedly heated and cooled.

In the uniflow design the steam always moves in one direction from the inlet port at the end of the cylinder to exhaust through a ring of ports in the middle of the cylinder. The piston is very long and acts as its own valve, uncovering the ports at the appropriate point in the stroke.

Whilst there had been a number of early attempts to develop this technology, it was not until the work of Professor Stumpf in Berlin in the early 1900's that the design was widely introduced, initially on the Continent but increasingly, from 1909 onwards, produced under licence by many builders in the UK. This engine is a small example and was manufactured in 1926 by Robey's of Lincoln with a cylinder of 13.5" diameter and stroke of 16" to run at 200 rpm with steam at 200 psi and 150 DegF of superheat. It was initially installed at the Baltic Sawmills in Ammanford, South Wales but was moved to the laboratories of the Manchester College of Technology (like the cross compound engine) in 1938. Removed in 1947 by Thomas Mitchell Ltd of Bolton, it was purchased by the Society, with financial assistance from the Science Museum PRISM fund, in 1987.

Drop valves are fitted to each inlet port, with trip gear driven from eccentrics on a side-shaft. A shaft governor controls the engine speed by varying the angular position of the eccentrics, thus altering the point of cut-off on the stoke. Under normal running conditions the engine needs no exhaust valves, relying on the central cylinder ports, but for starting purposes, before the vacuum has built up in the condenser, a set of supplementary (conventional) exhaust valves are brought into use. .